-

PACK

Packaging equipment

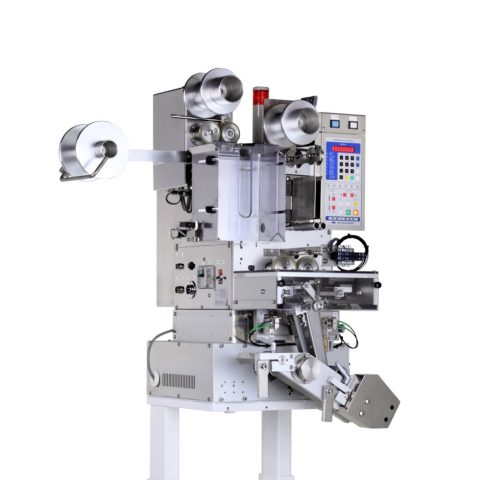

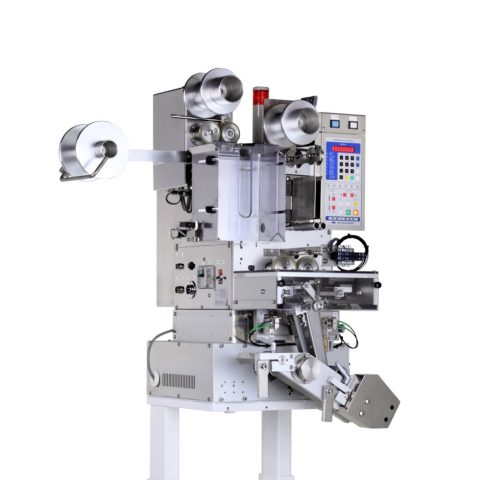

KD-820 Touch Panel Control Board

The pouch dispenser can be operated on the touch panel. The operation method is simple and error displays are clear so the device can be used even more easily.

KD-820&LV-100

The device consistently cuts continuous packaging pouches into one pouch (multiple pouch units are also possible) at a time, and adsorbs/loads them in place on a conveyor line at a high speed. The device can be used for various types of pouches including powders, drying agents, oxygen absorbers and liquids.

KD-820&LV-200

The device consistently cuts continuous packaging pouches into one pouch (multiple pouch units are also possible) at a time, and loads the adsorbed pouches in place such as on a conveyor line at a high speed without error. The device can be used for various types of pouches including powders, drying agents, oxygen absorbers and liquids.

KD-820&KK-360

The device consistently cuts continuous packaging pouches into one pouch (multiple pouch units are also possible) at a time, and loads them by automatically following the packaging device’s conveyor speed. The device can be used for various types of pouches including powders, drying agents, oxygen absorbers and liquids.

KD-920

The device consistently cuts continuous packaging pouches into one pouch (multiple pouch units are also possible) at a time, and loads them in place such as on a conveyor line.

KD-920-OH

The device consistently cuts continuous packaging pouches into one pouch (multiple pouch units are also possible) at a time, and loads them by automatically following the packaging device’s conveyor speed. The device can be used for various types of pouches including powders, drying agents, oxygen absorbers and liquids.

KD-4010

The device cuts continuous packaging pouches into one pouch (multiple pouch units are also possible) at a time with a high-speed rotary cutter, and loads them by automatically following the packaging device’s conveyor speed. This is the latest high speed loading device that was realized by the development of a feed and rotary type cutter synchronized with the transport timing of the packaging device conveyor.

KS-810

This device notches and cuts each pouch (multiple pouch units are also possible) of the continuous packaging.

KS-2200

This device notches and cuts each pouch (multiple pouch units are also possible) of the continuous packaging with a high-speed rotary cutter.

KS-5000

This device notches and cuts each pouch (multiple pouch units are also possible) of the continuous packaging with a high-speed rotary cutter.

KE-354

This device is connected to various three-sided and four-sided seal filling/packaging machines to fold continuous packaging pouches in fixed quantities and load them into boxes.

KE-1010X

This device is connected to various three-sided and four-sided seal filling/packaging machines to fold continuous packaging pouches in fixed quantities and load them into boxes.

FW-1000

This device is connected to various three-sided and four-sided seal filling/packaging machines to wind continuous packaging pouches in fixed quantities.

FW-2000

This device is connected to various three-sided and four-sided seal filling/packaging machines to wind continuous packaging pouches in fixed quantities.

CS-150W( Discontinued product )

This device aligns and packs into boxes pouches that are cut into single unit or continuous packages in multiple units with a filling/packaging machine.

CS-300

This device aligns and packs into boxes pouches that are cut into single unit or continuous packages in multiple units with a filling/packaging machine.

CD-820

This device loads various cards, cardboard, trays and lids onto a fixed position of the conveyor line.

Stable motion trajectory and smooth movement gentle to cards are realized with our original cam rack mechanism.

CD-920

This device loads various cards, cardboard, trays and lids onto a fixed position of the conveyor line.

Stable motion trajectory and smooth movement gentle to cards are realized with our original cam rack mechanism.

CD-870SLIM

This device loads various cards, cardboard, trays and lids onto a fixed position of the conveyor line.

Stable motion trajectory and smooth movement gentle to cards are realized with our original cam rack mechanism.

TM-200

This device attaches double-sided tape to the continuous packaging pouches.

SMF Series

After cutting the pouches filled with powder or liquid such as soup or condiments, this multi-row distribution device places them at a regular interval and loads them into multiple containers placed and transported in parallel all at once.

It is used together with the pouch dispenser.

SMV Series

After cutting the pouches filled with powder or liquid such as soup or condiments, this multi-row distribution device places them at a regular interval and vacuums/loads them into multiple