Power Transmission

-

Multiple or single-position tooth clutches are positive engagement devices having open or nickel-plated, enclosed housings. Tooth clutch designs include a pilot-mount version (accepts sprockets or couplings), a flange-mount version that connects to bearing-supported devices and integral sprocket versions. Air-engaged tooth clutches produce up to 60,000 in-lbs. torque. Spring engaged tooth clutches, with up to 72,000 in-lbs. torque, are the ultimate holding device. Single and double-flex couplings, specifically designed for high-torque tooth clutches, are used for inline shaft connections.

-

Friction brakes have a stationary pad (friction facing) and a rotating wear surface. Common configurations include drum brakes, caliper disc brakes and shaft-mounted brakes with an integral disc and rotor. Friction brakes provide controlled deceleration, stopping, holding, and tension control. Air and spring-engaged versions are available in all brake configurations.

-

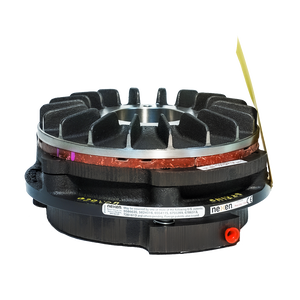

Nexen’s Friction Clutch-Brakes combines the features of a Friction Clutch with a Friction Brake into a single unit. Standard models offer pilot mount, sheave mount and pilot mount with coupling half options. Pilot Mount units are available in various standard bores sizes with customization possible with bushings and couplings.

-

A torque limiter protects mechanical equipment or its work from damage by mechanical overload. A torque limiter may limit the torque by slipping a friction plate clutch or disconnecting the load entirely. The action of a torque limiter is useful to limit any damage to the machine or product due to mechanical failures or product jams in the machine and is typically installed on the output side of gear reducers to protect the gear set.

-

Precise tension control is vital to any web or strip-fed operation, and the product must be fed under tension, processed under tension and wound up again under tension. Tension controllers are an integral part of maintaining this set tension. Nexen tension controllers range from simple systems with diameter feedback (open loop) to dancer control systems and the highest precision systems using web tension sensor feedback (closed loop).